| REMOVE THE ALTERNATOR

Here I can only talk about the

Bosch and Saprisa alternators, on the newer models I

have not worked yet. First remove the 8mm Allan head

screw of the rotor. The screw doesn't have to be

tightened too much, as the cone fixes the rotor on the

crankshaft. To remove the rotor you need a small tool

with which to squeeze the rotor of the crankshaft. You

can buy this at your local dealer, but it is very

simple to make. Go to builders square next door and

look for a hard metal pin 6x55mm. Completely thrifty

people can also shorten an old 6mm screw to

corresponding length. This little thing you put in the

screw hole, take an old 8mm bolt, and screw it in.

Suddenly the rotor will come off.

|

| REMOVE THE GEAR BOX

The construction of the Guzzi

frame is, in regard to the gearbox removal, a

completely stupid design. When you want to work on the

clutch or the gearbox, you have to take apart the

whole motorcycle. It is at least, even with experience

a 1,5 hour job. Usually you remove the whole frame

from the engine. At assembly it takes a lot of time to

fit the lower frame into the upper frame again. Here

you can spare some work and time, if you take out not

only the rear wheel but also the front wheel. Keep the

long engine bolt under the alternator in place, only

loosen it, and turn the frame around this front screw

and support it with a piece of wood facing the engine

block in the area of the distributor. Now you can

reach the gearbox under the frame.

|

| CLUTCH REMOVAL AND INSTALLATION

Without the special tool this is

not that easy. Try to hold the flywheel with a stabile

screwdriver and loosen one of the screws. Done this,

you've won. Now take an old screw, screw it in and

connect this with any kind of tool or metal with one

of the struts from the engine housing.

Behind it the clutch you can

find the clutch plates, the pressure ring and the

ground ring, behind which the springs are. But STOP,

before simply ripping everything out, have a close

look onto the ground plate. There is a little punch

hole on one tooth. I would recommend to make punch

holes into the clutch on each side of this one, so

that you are able to mount it in the right position.

If you were too fast, there is an explanation, which

is too long to describe, and when I did that once, I

did it twice and had the feeling it wasn't right. If

you have done it wrong, you can feel riding the first

yards, the clutch doesn't disconnect properly. That's

because the springs are not working in axial

direction.

Also the crankshaft has a mark,

which determines the position of the clutch. Also here

I have immortalized the painted mark with a punch

hole. You discover the screws of the clutch, which you

can also loosen with the method described above.

The installation happens in

reverse sequence, whereby the problem is the alignment

of the teeth of the clutch and the distance plate on

the one hand and center this whole package to the

crankshaft on the other. The easiest is, if you have a

spare or used gear from the transmission, otherwise

you have to detach the one from the gear box. For even

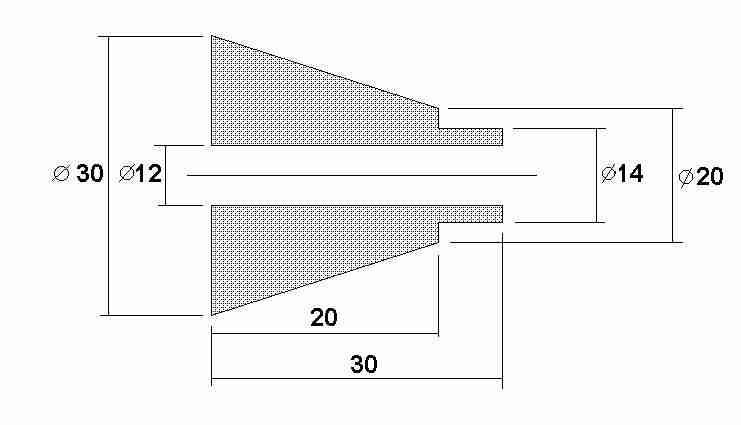

more convenience I have got another tool made on a

lathe, a little cone sketched below (sorry, sizes in

mm again). Furthermore you need from a very well

stocked hardware store a M12x100x1.5 screw. Head and

coating doesn't matter.

Screw the gear with the cone into the crankshaft, put

the springs in (to glue them for a moment you can use

a tiny bit of copper paste), put the ground plate in

place and feel with a finger, if all springs are in

their holes. Then put the first clutch plate in, the

distance plate and the second clutch plate (both

clutch plates with the collar to the rear), attach the

starter circle with two springs to the clutch housing.

Tighten them slowly and check if the distance plate

moves in its place. If you have assured this, you can

tighten all others as well, using the method above to

tighten all except one. The last one you can tighten

with the help of the screwdriver. Take out the gear

and the bolt. Don't forget the little pusher, which

belongs to the bottom of the clutch onto the pressure

plate.

If you don't have a cone, you

are depending on your best guess and have to use a

light to check through the holes, if everything

aligns. But that will never be as accurate and worst

case will be, that you can't mount the gearbox.

If you have done it right, you

can push the gearbox more or less easily into the

clutch.

|